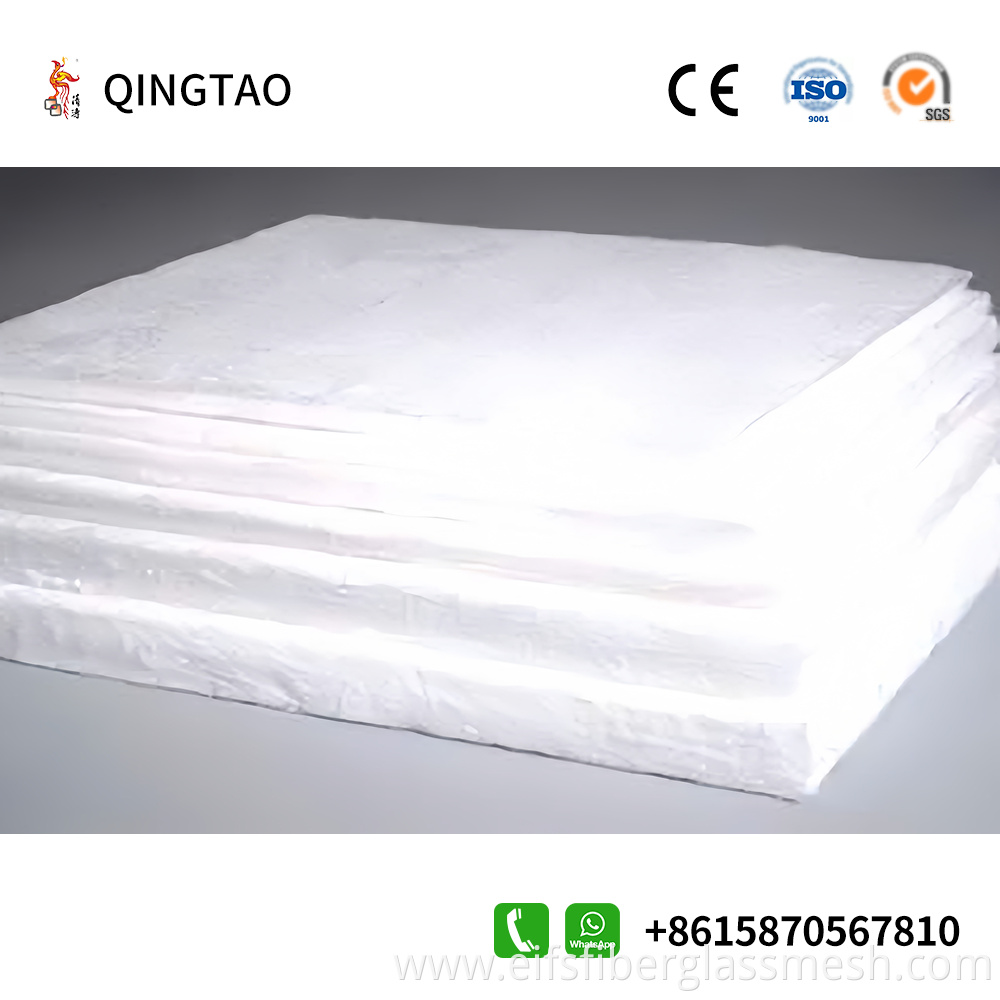

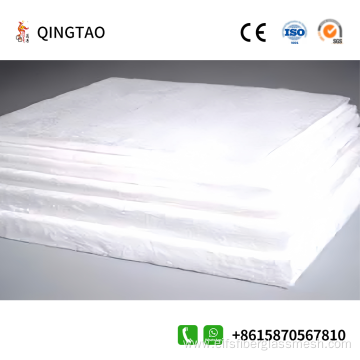

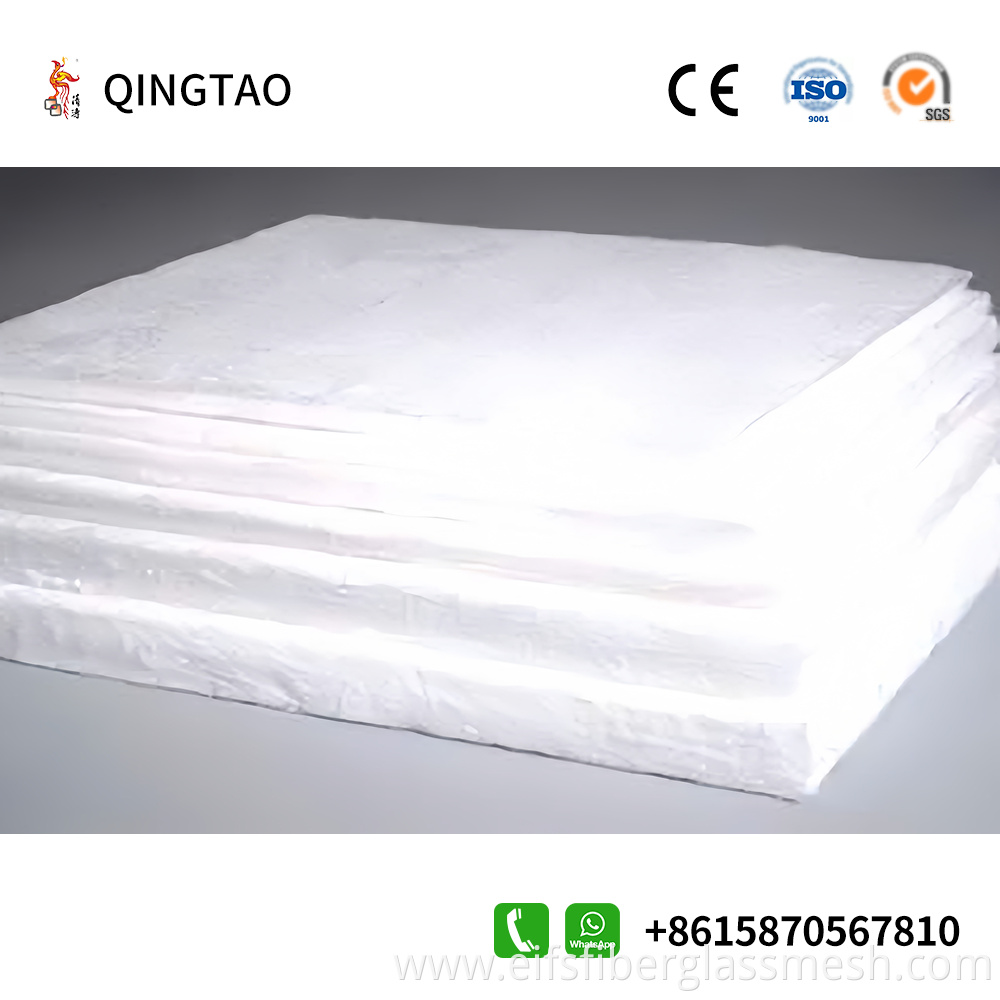

Fiber chopped strands are chopped warps of glass rovings and are suitable for reinforcing thermoplastics. Typical products include mechanical products, auto parts, electronic and electrical parts, etc. At the same time, it can be widely used as building and waterproofing materials, plastic floor base materials (Fiber Glass), heat insulation materials, fiberglass paving paper, battery insulation boards(Glass Mat), air filter mat materials (Fiberglass Cloth), reinforced gypsum, etc. Except for the alkali-resistant type used in the construction field, other types are mainly alkali-free. 1. Wire diameter: 7-13um 2. Commonly used wetting agent types: silane, starch coating 3. Chopped length: 3mm 4.5mm 6mm 9mm 12mm 24mm. (Special specifications Can be customized upon request). 4. Resin used: PA PBT pet PP up, etc. 5. Water content: 0.10%, 8-10% (wet chopped shreds)

Except for the alkali-resistant type used in the construction field, other types are mainly alkali-free. 1. Wire diameter: 7-13um 2. Commonly used wetting agent types: silane, starch coating 3. Chopped length: 3mm 4.5mm 6mm 9mm 12mm 24mm. (Special specifications Can be customized upon request). 4. Resin used: PA PBT pet PP up, etc. 5. Water content: 0.10%, 8-10% (wet chopped shreds) 6. Content of combustible substances: 0.2%

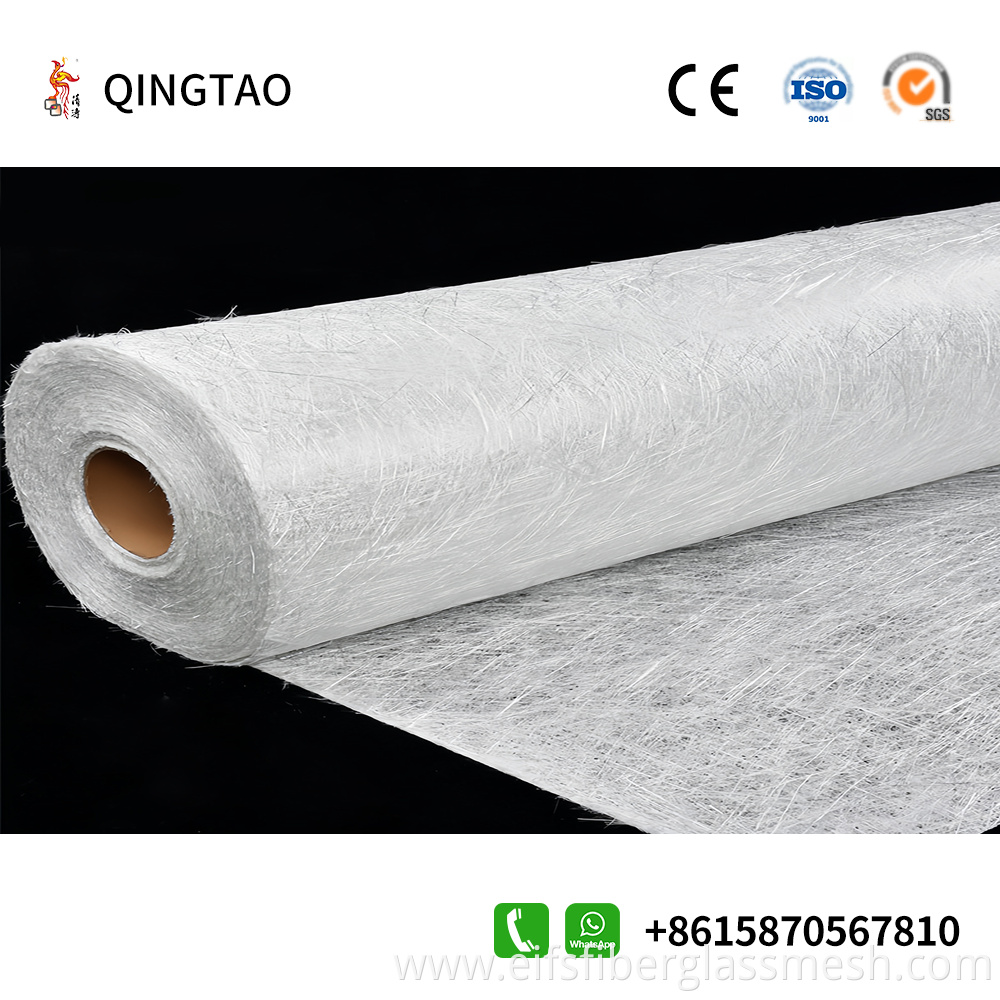

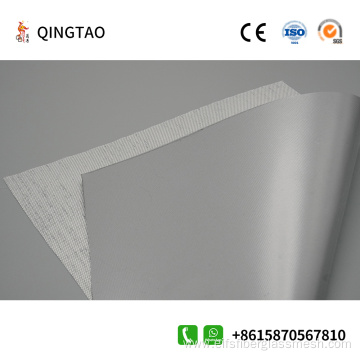

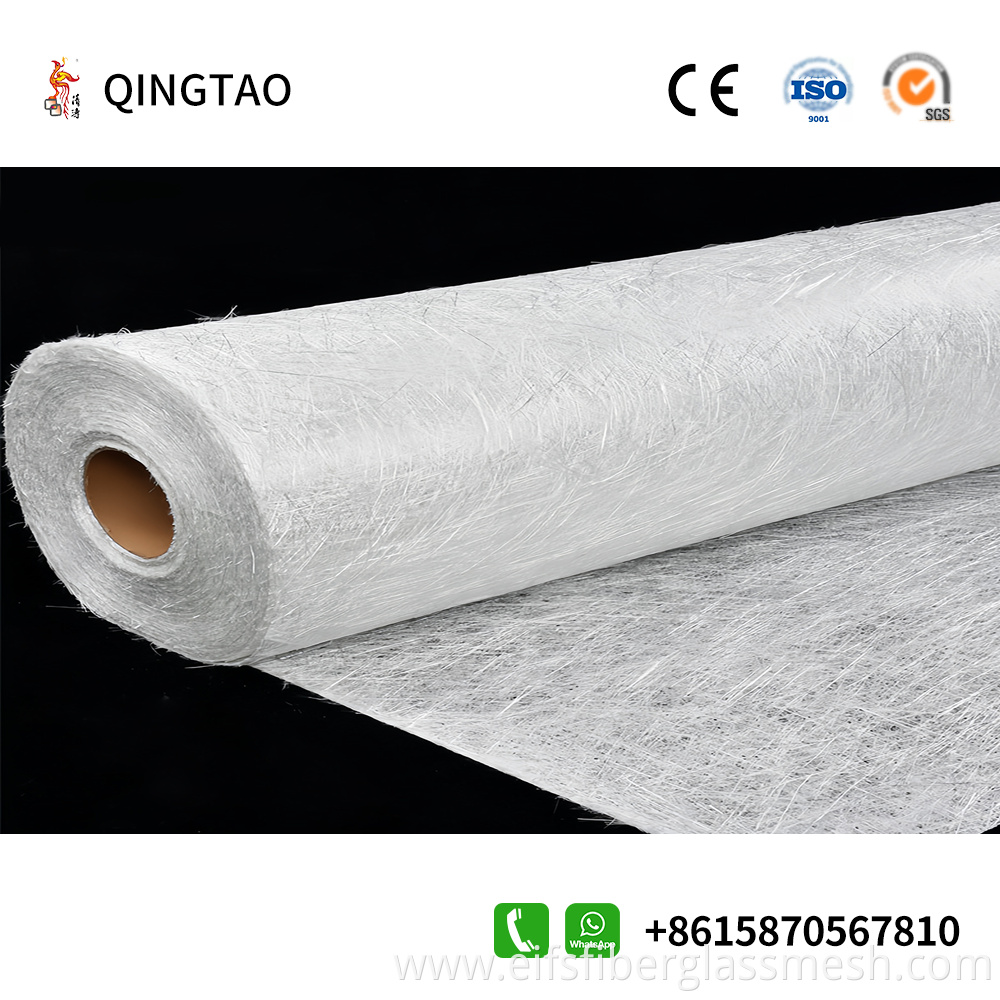

1. Hand lay-up: The hand lay-up process is the main method of FRP production in my country. Fiberglass cloth mat, continuous mat ,roll mat and stitched mat can all be used in the hand lay-up process. The use of stitched felt can reduce the number of laying layers and improve the efficiency of hand lay-up operations. However, because the stitch-bonded felt contains more chemical fiber stitch-bonded threads, the bubbles are not easy to drive away. FRP products have more needle-shaped bubbles, and the surface feels rough and not smooth. In addition, stitchbonded felt is a heavy fabric, and its mold coverage is poorer than cut felt and continuous felt. When making products with complex shapes, it is easy to form holes in the bends. The hand lay-up molding process requires that the felt sheet has fast resin penetration, easy elimination of bubbles and good mold of covering.

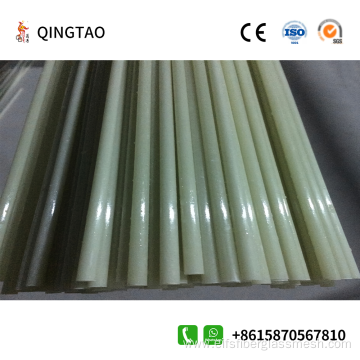

2.Pultrusion: It's process is one of the main uses of continuous felt and stitchbonded felt. Generally, it is used in combination with twistless roving. Using continuous felt and stitch-bonded felt as pultruded products could significantly improve the circumferential and transverse strength of the product and prevent cracking of the product. The pultrusion molding process requires the felt to have uniform fiber distribution, high tensile strength, fast resin penetration rate, good softness and mold filling properties, and the felt should have a certain continuous length.

3.RTM:The Molding of Resin Transfer Molding (RTM) is a closed molding process. It consists of two halves, a female mold and a male mold, a pressurizing pump and an injection gun, without the need for a press. The RTM process usually uses continuous felt and stitchbonded felt instead of chopped strand felt. The felt sheet is required to have the characteristics that the felt sheet should be easy to be soaked by resin, good breathability, good resin erosion resistance and good mold covering ability.

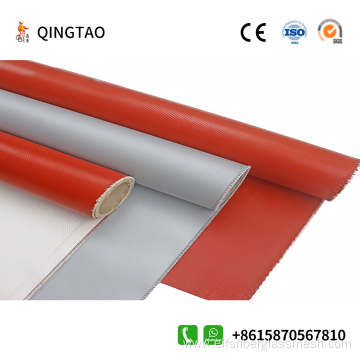

4. Winding process: Chopped strand felt and continuous felt are generally used for winding molding, mat roll which is mainly used as the resin-rich layer of the product, including the inner lining layer and the outer surface layer. The requirements of the winding molding process for Glass Fiber mat are the same as 5. Centrifugal casting molding: Chopped strand mat is usually used as raw material. Roofing mat or the chopped strand mat is placed in the mold in advance, and then the resin is added into the rotating open mold cavity, and the air bubbles are discharged through centrifugation to make the product dense. The felt sheet is required to be easy to soak and have an outstanding of breathability.