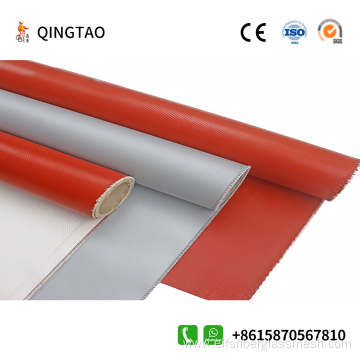

Chopped (Glass Mat) strand mat is made of E/C chopped strands (Fiber Glass) randomly distributed and bonded with powder or emulsion polyester binder. The mat is compatible with unsaturated polyester,(Fibreglass mat) vinyl ester and various other resins. Mainly used in hand lay-up, fiber winding and molding procedure. Typical FRP products include plates, storage tanks, ships, pipes, etc.

Procedure of the production

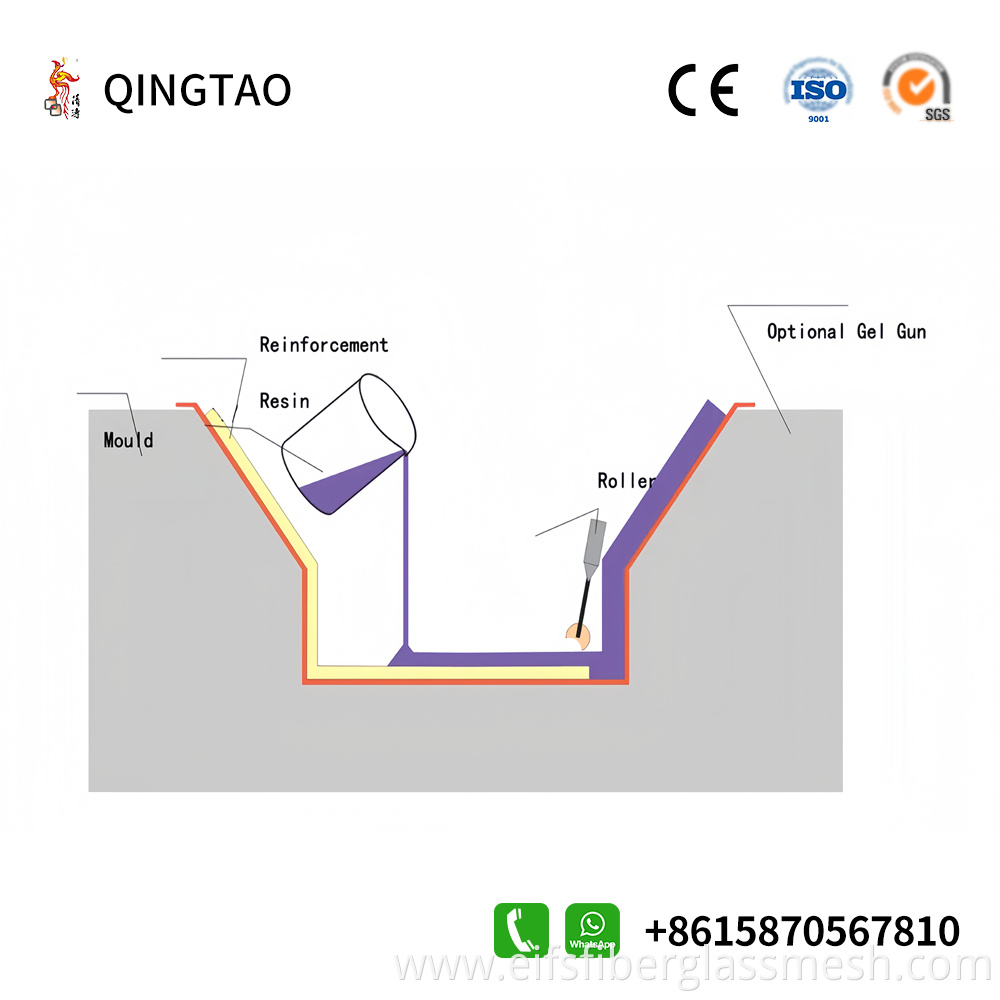

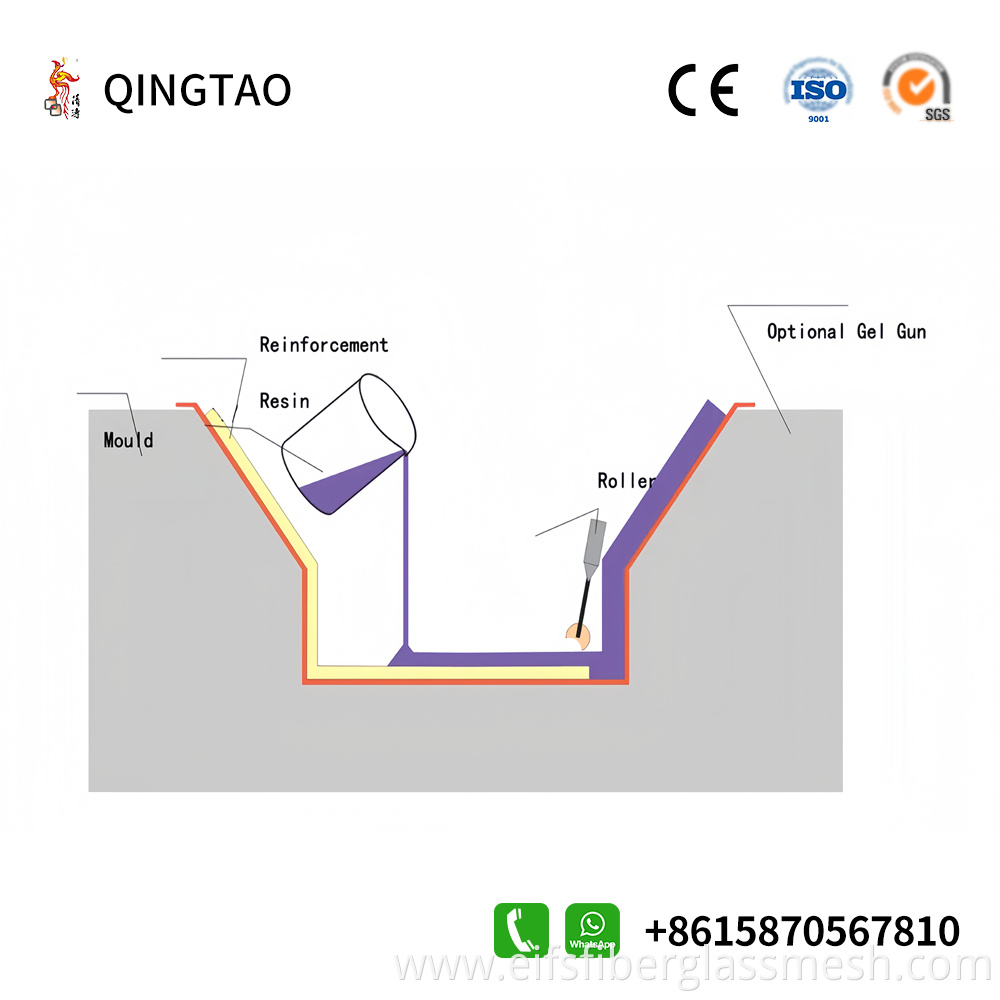

Handmade lamination Procedure

Reinforcement material's type of fiberglass strands (Fiberglass Cloth) , mats, or woven rovings is first placed into a mold coated with a release agent and gel coat. The resin mixture is then applied by hand using a brush or airbrush. This is then used to ensure even impregnation, complete wetting of the glass and removal of any trapped air bubbles. Repeat this operation until the desired thickness of the structure is obtained. After curing at room temperature / under heat, the finished part is formed.

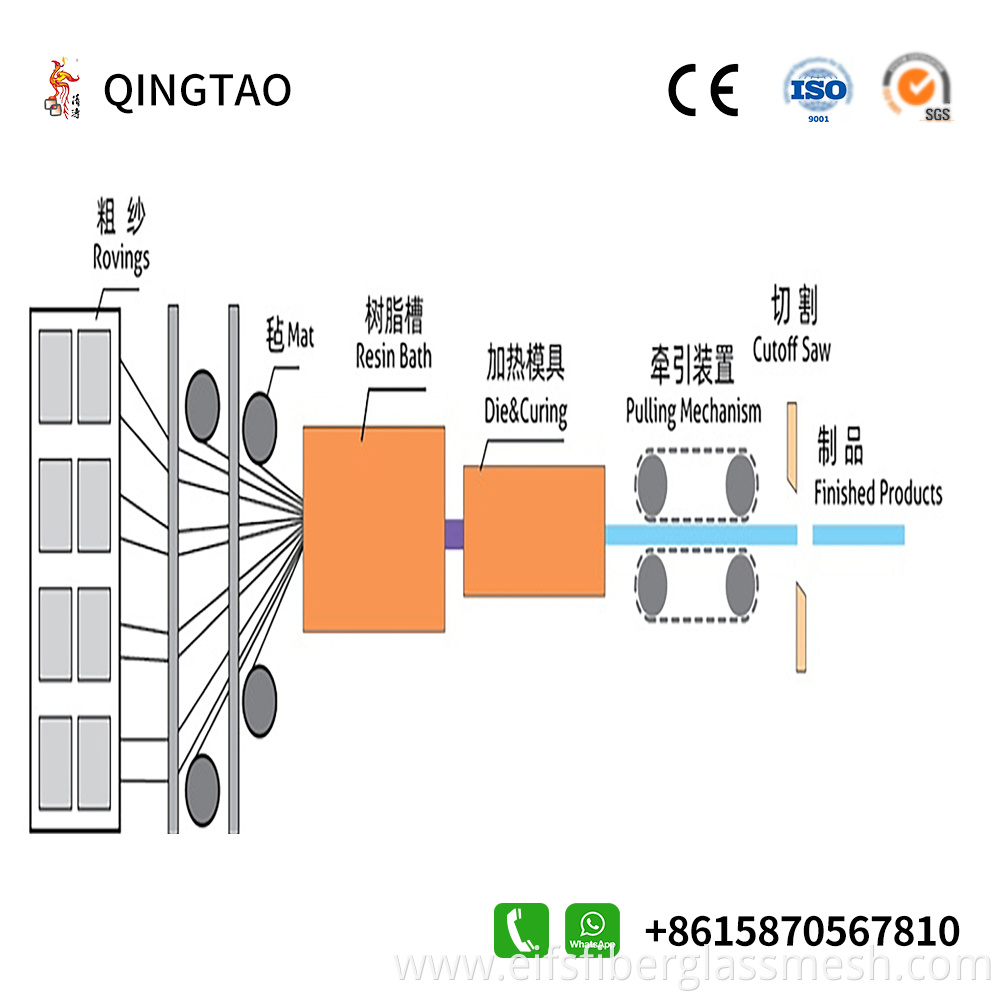

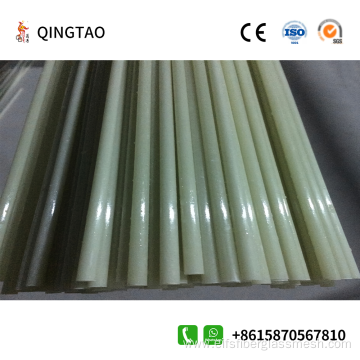

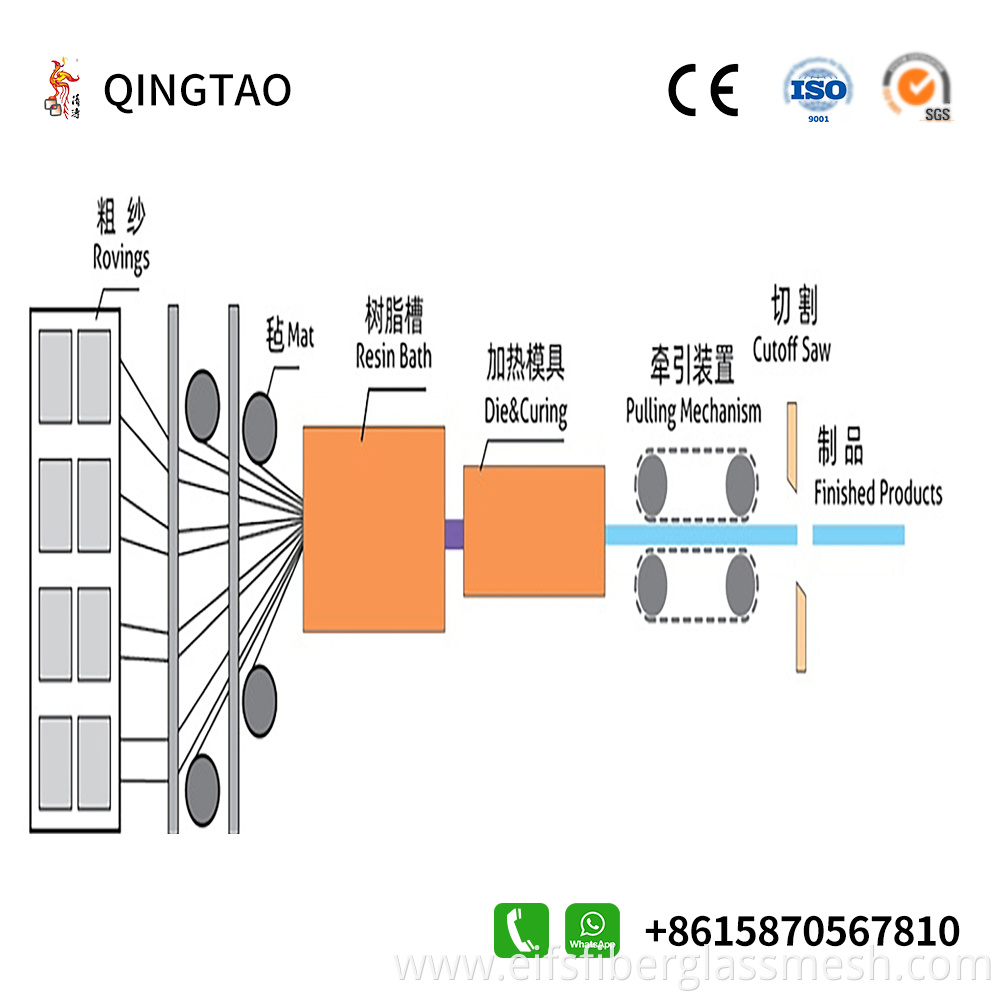

Pultru-sion Procedure

Rovings, mats or other fabrics are pulled through a resin impregnation bath and then into a heated die using a continuous pulling device. The final product is formed under high temperature and high pressure conditions.

Continuous Panel Molding Process

Continuous Panel Molding Process

A controlled amount of the resin mixture is deposited uniformly onto the moving film at a constant speed. The thickness of the resin is controlled by a broach. Fiberglass rovings are chopped and evenly distributed over the resin. The top film is then applied to form a sandwich structure. The wet components are passed through a curing oven to form composite panels.

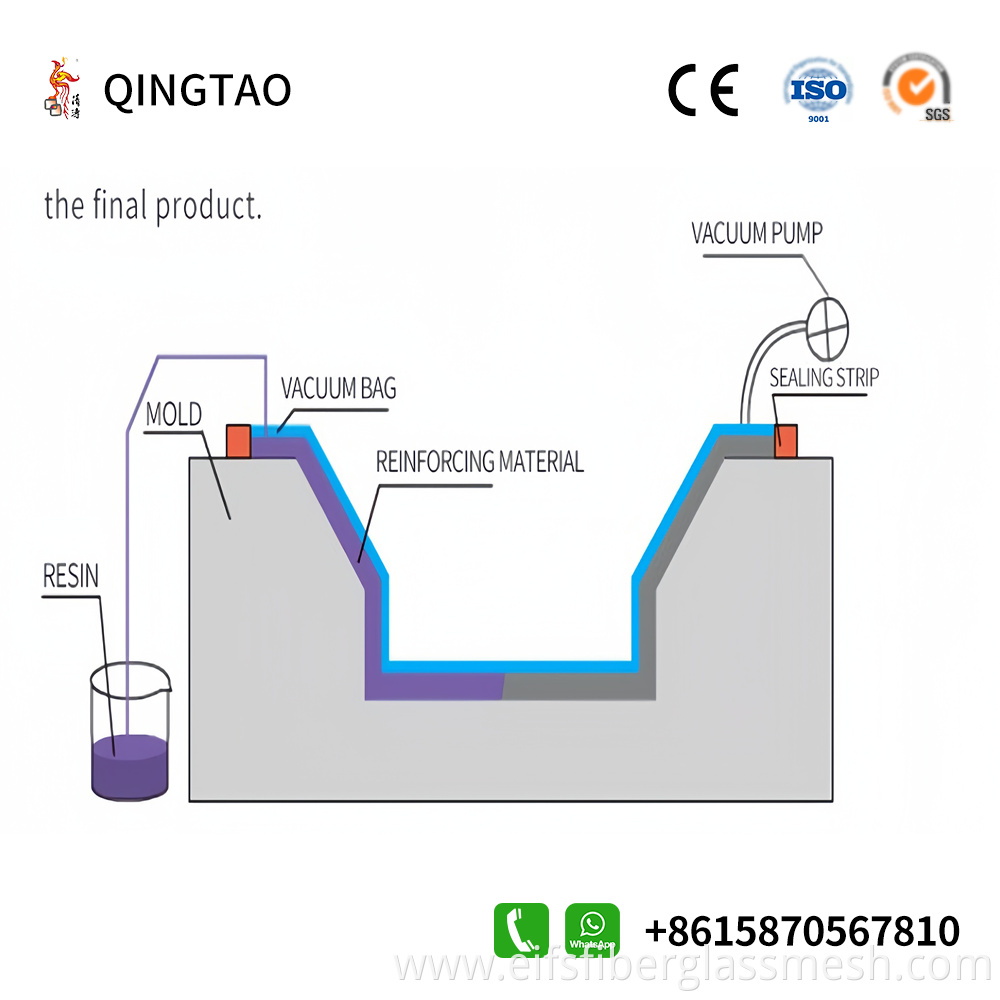

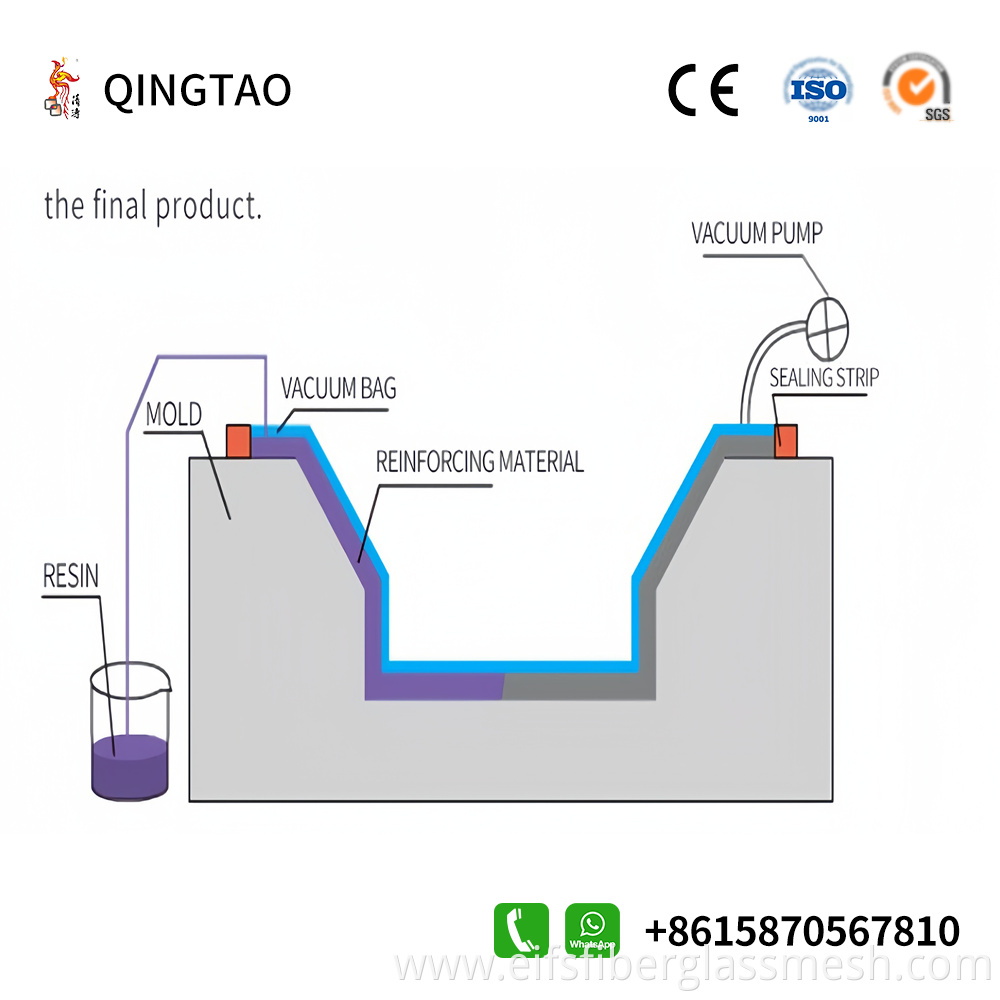

Vacuum Pattern Model

It involves laying reinforced material into a mold, covering the entire layer with a vacuum bag, sealing the periphery with a sealant, and then sucking in the resin in a vacuum. The resin completely penetrates the reinforcement and cures to form the end of product,chopped strand mat,Building Mat,Fiberglass Batt.

| Item | Standard Weight | Width(mm) | Loss On lgnition | Moisture(%) | Compatible |

| (g/m2) | (%) | Resins |

| A | 225 | 1040/1270/2080≤3300 | 2-6 | ≤0.2 | UP VE EP |

| B | 300 | 1040/1270/2080≤3300 | 2-6 | ≤0.2 | UP VE EP |

| C | 380 | 1040/1270/2080≤3300 | 2-6 | ≤0.2 | UP VE EP |

| D | 450 | 1040/1270/2080≤3300 | 2-6 | ≤0.2 | UP VE EP |

| E | 600 | 1040/1270/2080≤3300 | 2-6 | ≤0.2 | UP VE EP |

| F | 900 | 1040/1270/2080≤3300 | 2-6 | ≤0.2 | UP VE EP |